Production

BASED IN BELGIUM

Our extensive production facilities located in Waregem, Belgium are equipped with the latest industrial equipment. These are adequate to produce the highest quality of fabrics and meet your specific requirements.

100% supply chain control

Our vertically integrated structure enables us to guarantee transparency and high-quality products. By total control of our own supply chain, we achieve the best results. The internalization of our processes starts with the obtaining of the yarns, up to the production of high-end garments with our fabrics.

Minimizing our Production's Ecological Footprint

We strive to a healthy planet that benefits all our stakeholders, including employees, customers, shareholders, suppliers and our communities.

Production Facilities

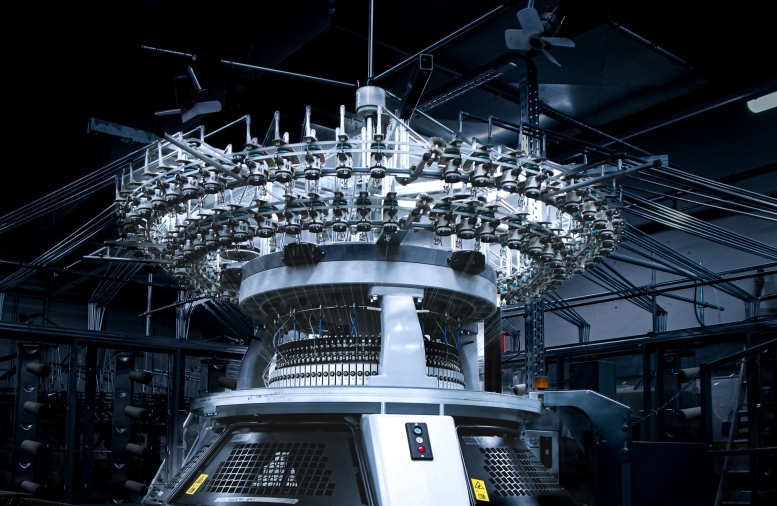

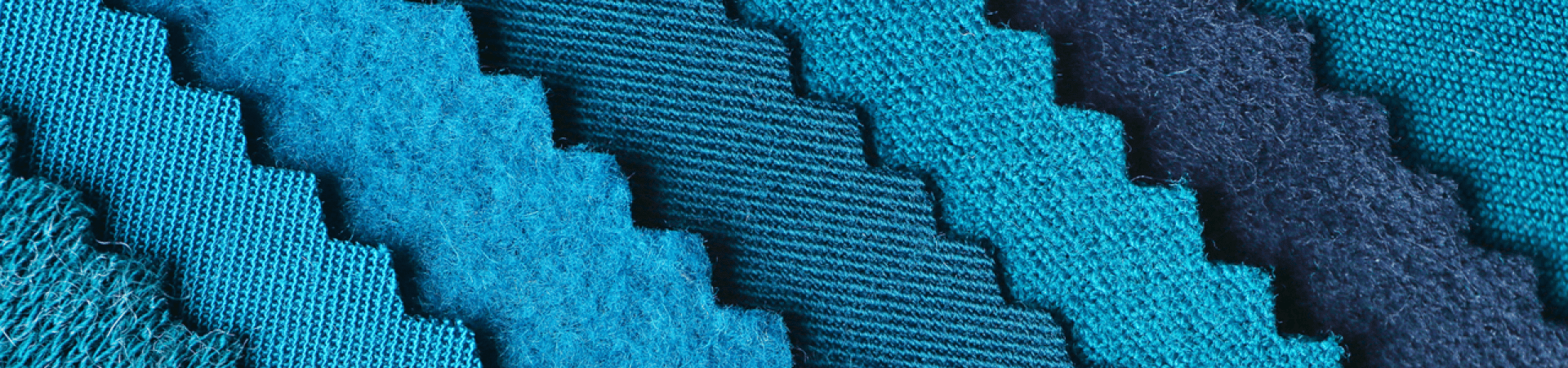

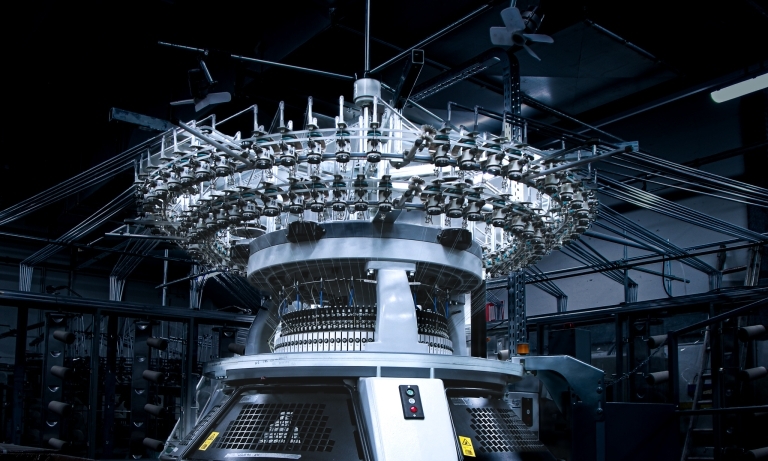

KNITTING PARK

Recently, our acquisition of knitting machine park enables us to serve our customers with an even wider range of high-quality textiles.

Our production site in Waregem offers a wide variety of single- and double-needle bed circular looms, 26" to 42" in diameter and 11 to 28 gauges. These machines allow the production of high-quality knitwear.

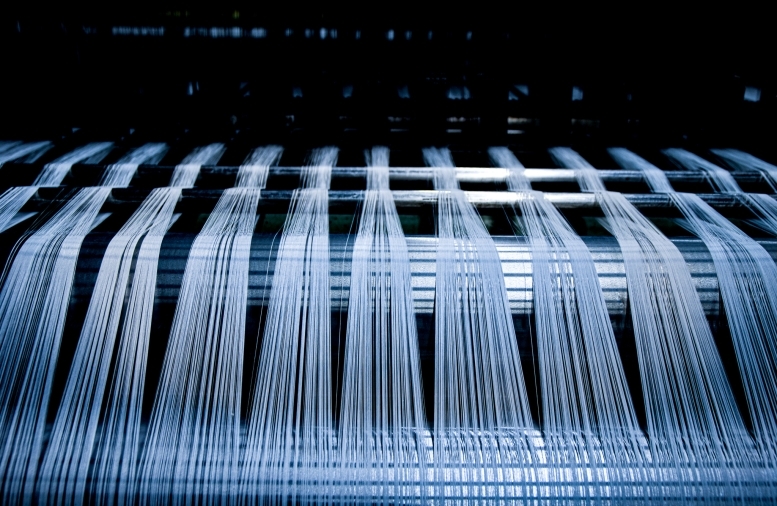

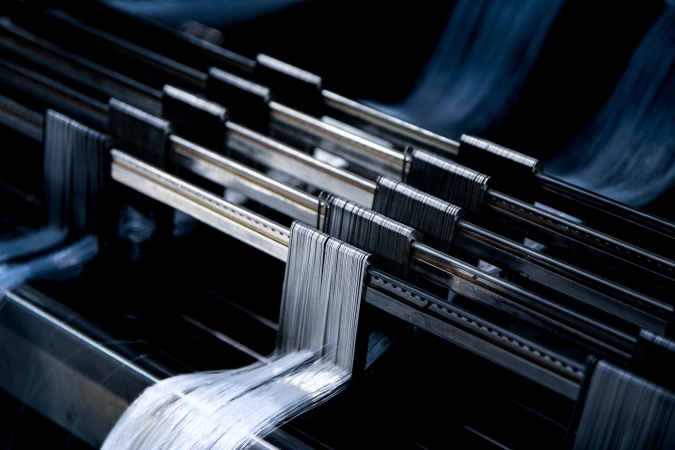

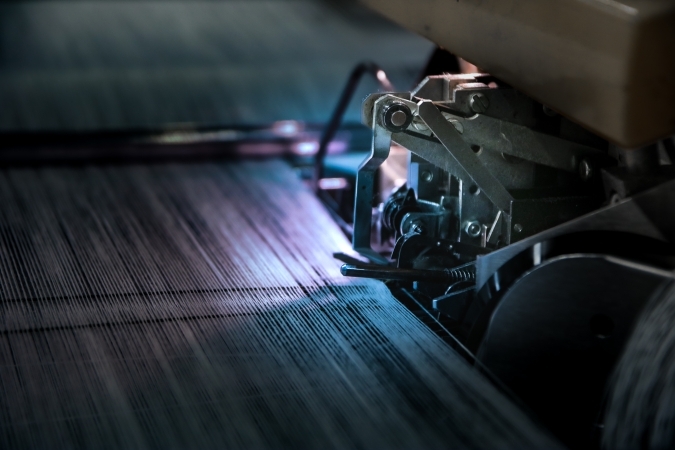

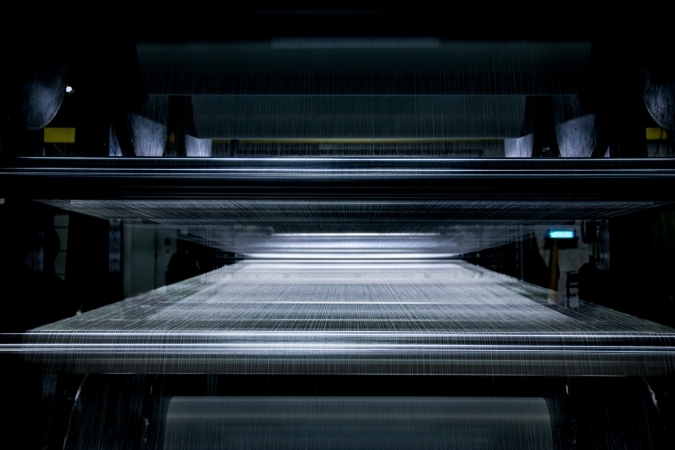

HIGH TECH WEAVING MILL

Always evolving and innovating, our production site evolved into a high-tech weaving mill, with all departments under one roof. We control the entire production flow, from sizing and warp beaming over weaving, dyeing, printing, finishing, coating and laminating fabrics. Everything is conducted on-site. With more than 150 looms, we're able to produce big woven fabric volumes for large-scale projects. In our production facility in Waregem, Belgium, you can find air, rapier and projectile looms which have each their own advantage.

DYEING impact

With five different types of dyeing machines, we always choose the most suitable machine based on the needs a particular quality must meet. This variety of equipment also ensures a flexible approach towards delivery time and capacity. By dyeing fabrics at lower temperatures, we reduce the water consumption of the dyeing process.

Reduced water & chemical consumption

Our latest acquisition in textile dyeing machinery enables us to reduce our water & chemical consumption up to 60% compared to previous installations. Of course the raft ratio is depending on the type of material that needs to be dyed.

Read more about our environmental impact.

Enabling fast production

In addition to the large reduction in water and chemical consumption, there is also a huge difference in the dyeing route because we are able to wetwind with our new winding machine. Wet winding has the advantage that the extension of the fiber by absorption of water can be absorbed during winding and the fabric is therefore less easily detached during dyeing.